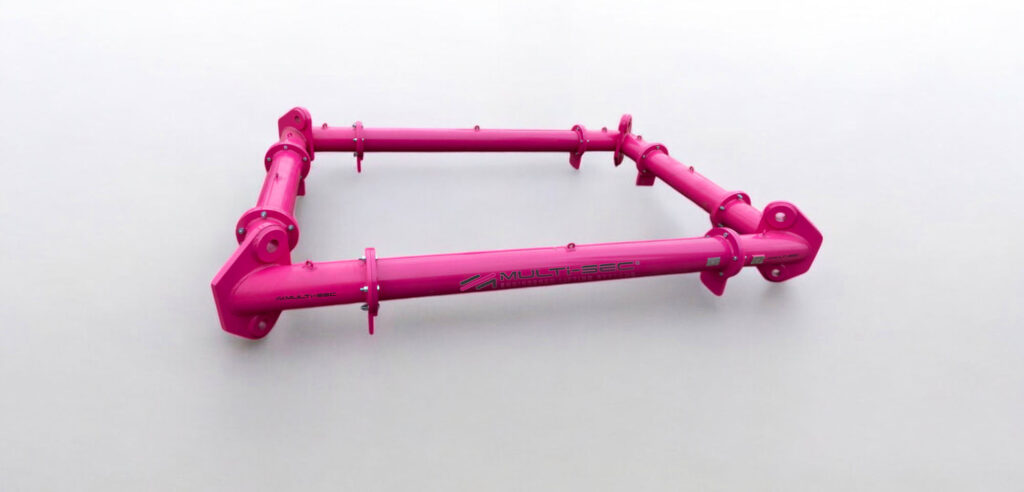

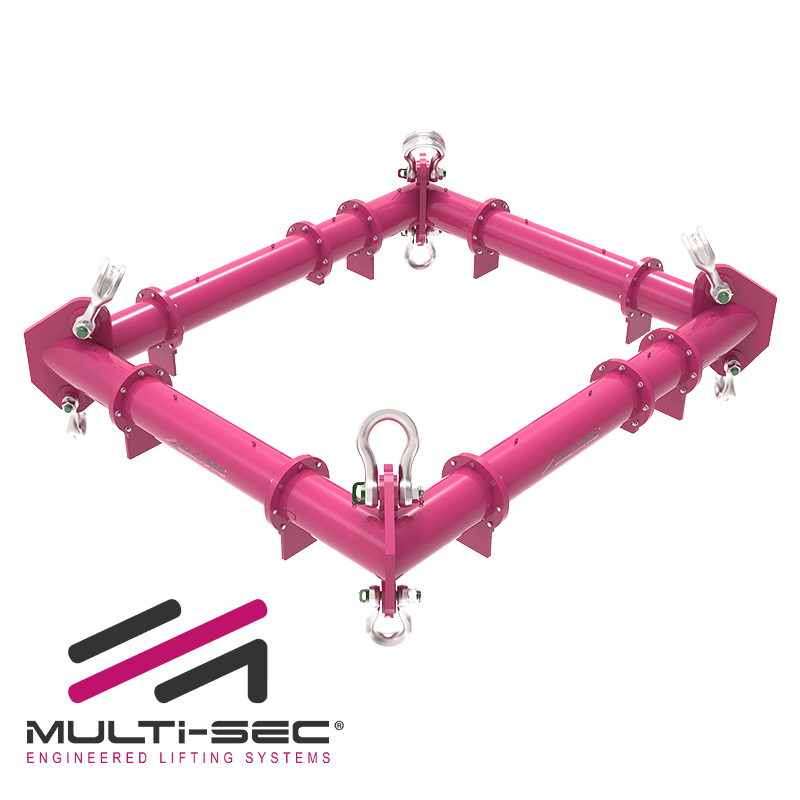

Modular Spreader Frames

Engineered Strength for Complex Lifts

Multisec Modular Spreader Frames are designed for safe, versatile, and heavy-duty four-point lifting operations. Built with precision-engineered corner units and struts, our frames provide a reliable solution for projects where standard spreader beams are not enough.

Key Features

Modular & Scalable – Easy to reconfigure for different lift sizes and load requirements

Corner Point Engineering – Upper and lower lifting lugs ensure stable load control

Customisable Solutions – Bespoke designs available for non-standard projects

Tested & Certified – Proof-load tested at Durham Lifting’s Britannia Testhouse

Onshore & Offshore Ready – Designed to perform in demanding conditions

Product Range

Multisec modular lifting frames combine the innovative design of the Multisec spreader beams and Multisec corner units to form a robust lifting frame to suit your specific lifting requirements Designed and manufactured in the UK in accordance with relevant standards for both onshore and offshore use, Multisec modular lifting frames for up to 250 Tonne are in stock and available immediately for worldwide distribution.

Multisec® Multi-CU 13

Up to 13T WLL

Spans Up to 6 x 6

Multisec® Multi-CU 25

Up to 25T WLL

Spans up to 7m x 7m

Multisec® Multi-CU 50

Up to 50T WLL

Spans up to 9m x 9m

Multisec® Multi-CU 75

Up to 75T WLL

Spans up to 12m x 12m

Multisec® Multi-CU 110

Up to 110T WLL

Spans up to 14m x 14m

Multisec® Multi-CU 170

Up to 170T WLL

Spans up to 15m x 15m

Multisec® Multi-CU 250

Up to 250T WLL

Spans up to 16m x 16m

Multisec Spreader Frames combine the proven design of our modular beams with robust corner units, creating a lifting system that adapts to your project needs.

Capacity: Up to 250 tonnes

Span: Up to 16 metres

Applications: Offshore wind, construction, heavy engineering, ports, and infrastructure projects

Flexibility: Configurable with additional struts to achieve multiple lifting geometries

Compliance: Designed and tested in line with LOLER, Eurocodes, and DNV lifting standards

Offshore wind turbine installation

Vessel and subsea structure lifts

Bridge and civil engineering works

Heavy industrial load handling

Port infrastructure projects

Safety is at the heart of every Multisec design:

Manufactured to strict quality standards

Designed with risk assessments and LOLER compliance in mind

Compatible only with the correct Multisec strut series for maximum safety

Clear certification, maintenance guidance, and full traceability with every frame

Enquiry Form

Ready to buy a Modular Spreader Frame for your next project? Call our sales team on +44 (0)1642 240 672 or fill in the form below for a quote and expert advice on the best lifting solution for your needs.